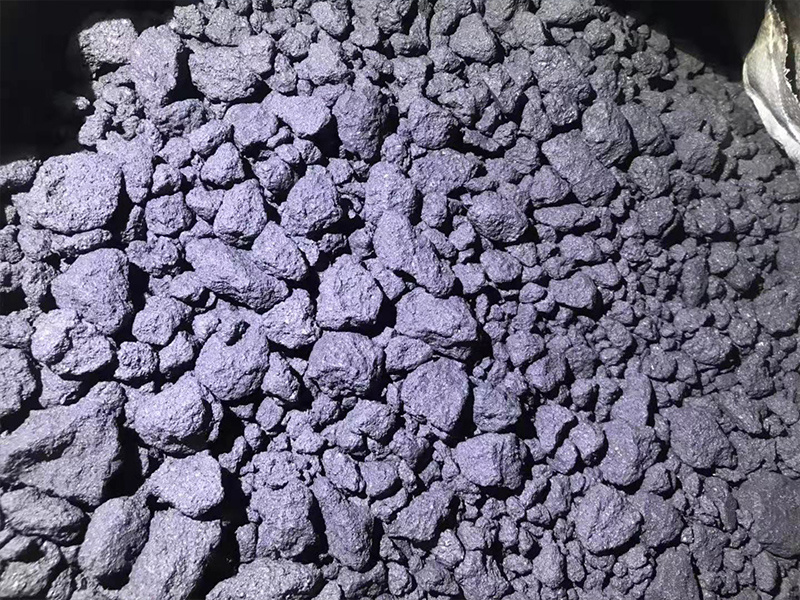

0-1mm carburetant

keyword:

carburetant

Category:

Product description

Technical description to graphite scraps

Graphite scraps are the scraps that failed to pass the tests after graphitization of carbon products as well as the cut off fragments produced during the machining process.

Graphite scraps are the fragments in graphite form. It’s an umbrella name for the scraps that failed to pass the tests after graphitization of carbon products as well as the cut off fragments produced during the machining process.

There are many types of graphite scraps, including graphite electrode scraps, graphite anode scraps, natural graphite scraps, etc. All segments in graphite form can be referred to as graphite scraps. Since graphite scraps have features like electrical conductivity, thermal conductivity, high temperature resistance, low ash content, good chemical stability, etc., they are widely used as carburetants for steel furnaces, reductant for chemical engineering, and as one of the important raw materials for production of carbon products such as carbon electrodes, electrode pastes and anode carbon blocks for aluminum electrolysis.

Physicochemical indexes for graphite scraps

|

Indexes |

Unit |

Typical value |

|

True density |

g/cm³ |

≥2.18 |

|

Powder resistivity |

µW·m |

≤120 |

|

Ash content |

% |

≤0.5 |

|

Sulfur content |

% |

≤0.5 |

Related products

Product inquiry

Wanji Holding Group Graphite Products Co., Ltd.

Service hotline:+86 0379-67328777

Recruitment telephone: +86 0379-67328777

Add:Wanji Industrial Park, Xin’an County, Luoyang, Henan Province

Esperanto

Esperanto

Shqiptare

Shqiptare

Euskara

Euskara

Zulu

Zulu

Latinus

Latinus

Cymraeg

Cymraeg

தமிழ்

தமிழ்

Slovak

Slovak

Slovak

Slovak

Afrikaans

Afrikaans

Copyright © 2023 Wanji Holding Group Graphite Products Co., Ltd. This site already supports ipv6