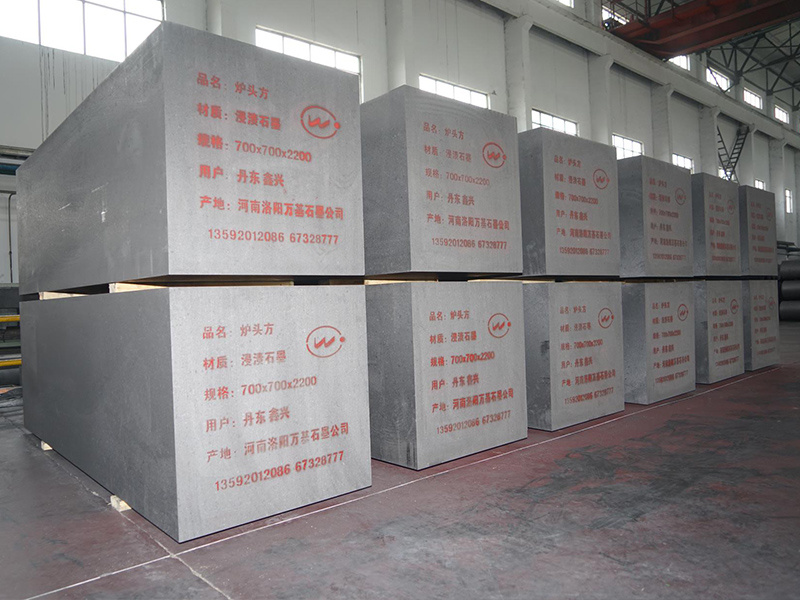

Graphitized furnace end rectangular electrode

keyword:

Graphitized furnace end rectangular electrode

Category:

Product description

Introduction to circular graphite electrode

1. Adopts imported German jolt moulding machine, featuring: 1) Vacuum-pumping; 2) Low porosity; 3) Even texture; 4) High volume density.

2. Adopts ring type baking furnace with cover, featuring: 1) Good heat insulation effect, so that the products are heated evenly; 2) Stable internal structure; 3) High coking value.

3. Adopts lengthwise graphitization furnace, featuring: 1) High conductivity efficiency; 2) Even degree of graphitization; 3) Stable product quality.

4. Adopts CNC combined processing machines: 1) High machining precision; 2) Good product appearance; 3) The advantages of graphite electrodes are easy processing, high removal rate for electrical discharge machining, and low graphite loss. 4) Graphite electrodes can be easily machined and its machining process can be way faster than that of copper electrodes. For example, when adopting milling process to machine graphite, its speed will be 2-3 times faster than other metals, with no extra manual treatment required. But copper electrodes will need manual grinding.

Physicochemical indexes for graphitized furnace end rectangular electrode

|

Indexes |

Unit |

Typical value |

Standard deviation |

Max. value |

Min. value |

|

Volume density |

g/cm³ |

1.7 |

0.015 |

1.75 |

1.7 |

|

True density |

g/cm³ |

2.2 |

0.015 |

2.23 |

2.19 |

|

Resistivity |

µW·m |

9 |

1 |

13 |

9 |

|

Resistivity |

MPa |

28 |

2 |

38 |

26 |

|

Ash content |

% |

0.5 |

0.2 |

0.8 |

|

|

Flexural strength |

MPa |

10 |

1 |

15 |

8 |

|

Porosity |

% |

22 |

1 |

24 |

21 |

|

Coefficient of thermal expansion (20-900) ℃ |

K-1×10-6 |

3.5 |

0.2 |

4 |

3 |

|

Electrolytic expansion rate |

% |

0.4 |

Related products

Product inquiry

Wanji Holding Group Graphite Products Co., Ltd.

Service hotline:+86 0379-67328777

Recruitment telephone: +86 0379-67328777

Add:Wanji Industrial Park, Xin’an County, Luoyang, Henan Province

Esperanto

Esperanto

Shqiptare

Shqiptare

Euskara

Euskara

Zulu

Zulu

Latinus

Latinus

Cymraeg

Cymraeg

தமிழ்

தமிழ்

Slovak

Slovak

Slovak

Slovak

Afrikaans

Afrikaans

Copyright © 2023 Wanji Holding Group Graphite Products Co., Ltd. This site already supports ipv6